North American Design & Application Methods

GENERAL DESIGN DETAILS

Sheathing:

Shingles and shakes shall be applied over spaced sheathing. Spaced sheathing is usually 1" x 4" of 1" x 6" softwood boards.Solid sheathing is acceptable and may be required in seismic regions or under treated shakes and shingles. It is recommended on shake applications in areas where wind-driven snow is common. Solid sheathing is usually wafer-board panels or plywood which provides a smooth base for roofing.

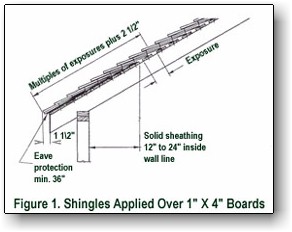

Shingles

There are two acceptable methods for application of spaced sheathing. One is to space 1" x 4" boards to coincide with the weather exposure of the shingles (Figure 1). Thus, if the shingles are to be laid at 5½" to the weather, the sheathing boards would also be spaced at 5½" on center. In this method of application each shingle is nailed to the center of the 1" x 4" board. In the second method of application, where 1" x 6" boards are used, two courses of shingles are nailed to each 1" x 6" board. (Figure 2) up to and including 5½" weather exposure. Although not commonly used, breather-type underlayment, such as roofing felt, may be applied over either solid or spaced sheathing.

Shakes

In shake application spaced sheathing is usually 1" x 6" boards spaced on centers equal to the weather exposure at which the shakes are to be laid - but never more than 7½" for 18" shakes and 10" for 24" shakes on roof installations. When 1" x 4" spaced sheathing is installed at 10" on center, additional 1" x 4" boards must be installed between the sheathing boards, A solid deck is recommended in areas where wind-driven snow is encountered.

Special care should be taken when installing the felt interlays over spaced sheathing to ensure that an effective baffle is formed (Figure 3). The felt should be applied over the top portion of the shakes and extend on to the spaced sheathing so that the bottom edge of the felt is positioned at a distance above the butt equal to twice the weather exposure. To be an effective baffle, the top of the felt must rest on the sheathing. The shakes should be placed so that the nails are driven through the upper portion of the sheathing board with the top of the roofing felt attached to the lower portion.

GENERAL APPLICATION DETAILS

Shingle Application

Regardless of style, the following basic application details (Figure 4 below) must be observed.

1) Shingles must be doubled or tripled at all eaves.

2) Butts of first course shingles should project 1½" beyond the fascia.

3) Spacing between adjacent shingles (joints) should be a minimum of ¼" and a maximum of 3/8".

4) Joints in any one course should be separated not less than ½" from joints in adjacent courses; and in any three courses, no two joints should be in direct alignment.

5) In lesser grade shingles containing both flat and vertical grain, joints should not be aligned with centerline of heart.

6) Flat grain shingles wider than 8" should be split in two before nailing. Knots and similar defects should be treated as the edge of the shingle and the joint in the course above placed 1½" from the edge of the defect.

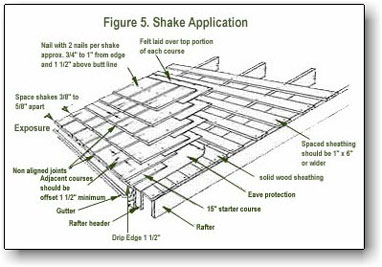

Shake Application

Shakes, like shingles, are normally applied in straight, single courses. The following application details (Figure 5 below) must be observed.

1) The starter course may be one or two layers of cedar shingles or shakes overlaid with the desired shake. A 15" shake is made expressly for starter and finish courses.

2) Butts of first course shakes should project 1½" beyond the fascia.

3) An 18" wide strip of No. 30 roofing felt (or No. 15 felt depending upon code requirements) should be laid over the top portion of the shakes and extend on to the sheathing. The bottom edge of the felt should be positioned above the butt of the shake at a distance equal to twice the weather exposure. For example, 24" shakes laid with 10" exposure would have felt applied 20" above the butt. Thus the felt will cover the top 4" of the shakes and extend up 14" onto the sheathing.

4) Spacing between adjacent shakes should be a minimum of 3/8" and a maximum of 5/8".

5) Joints between shakes should be offset 1½" over adjacent courses.

6) Straight-split shakes should be laid with the froe-end (the end from which the shake has been split and which is smoother) towards the ridge.